Collaboration with Omni Instruments Ltd.

We are happy to announce that we are starting a collaboration with Omni Instruments Ltd. in the UK. Omni Instruments Ltd. is developer and distributor of high definition measurement and logging systems. We have started the collaboration with offering two versions of the LPMS sensor system under the Omni Instruments brand. Please see the below links for further information:

LPMS-CU 9-Axis IMU AHRS Motion Sensor with CANbus and USB Connectivity

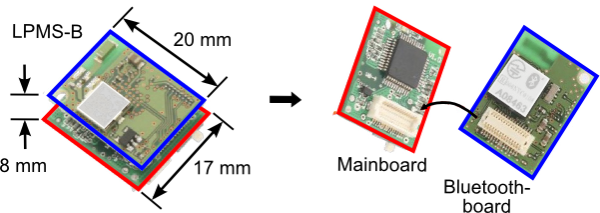

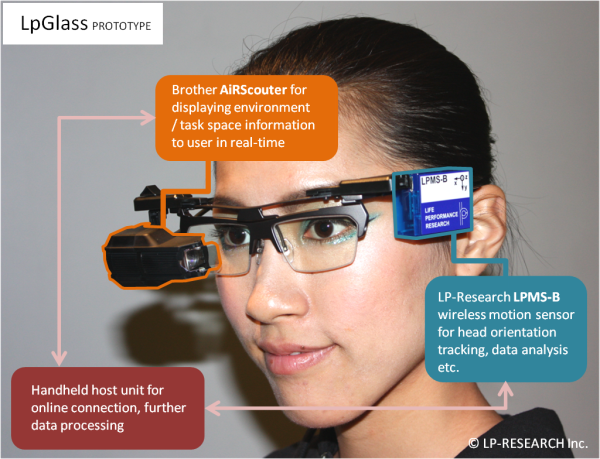

LPMS-B 9-Axis IMU AHRS Motion Sensor with Bluetooth Connectivity