Location-based VR Tracking Solution

LPVR Location-based VR Tracking Introduction

UPDATE 1: Full SteamVR platform support

UPDATE 2: Customer use case with AUDI and Lightshape

UPDATE 3: Customer use case with Bandai Namco

Consumer virtual reality head mounted display (HMD) systems such as the HTC VIVE support so-called room scale tracking. These systems are able to track head and controller motion of a user not only in a sitting or other stationary position, but support free, room-wide motions. The volume of this room scale tracking is limited to the capabilities of the specific system, usually covering around 5m x 5m x 3m. Whereas for single user games or applications this space may be sufficient, especially multi-user, location-based VR applications such as arcade-style game setups or enterprise applications require larger tracking volumes.

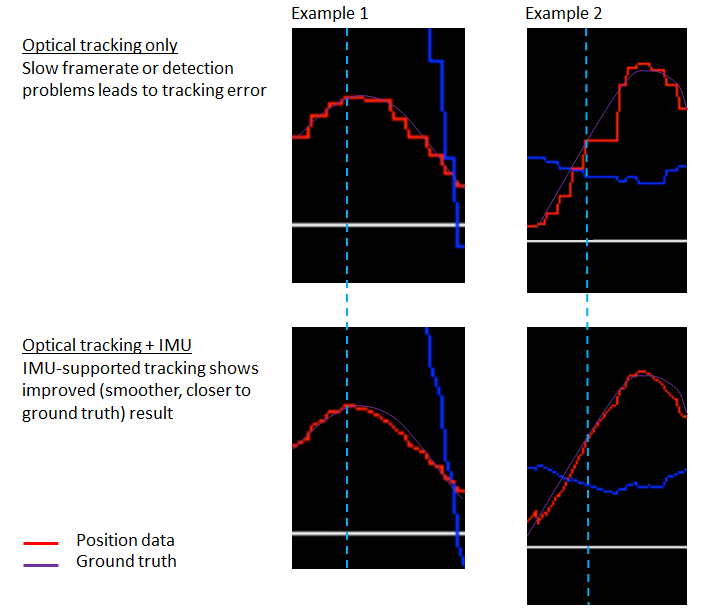

Optical tracking systems such as Optitrack offer tracking volumes of up to 15m x 15m x 3m. Although the positioning accuracy of optical tracking systems are in the sub-millimeter range, especially orientation measurement is often not sufficient to provide an immersive experience to the user. Image processing and signal routing may introduce further latencies.

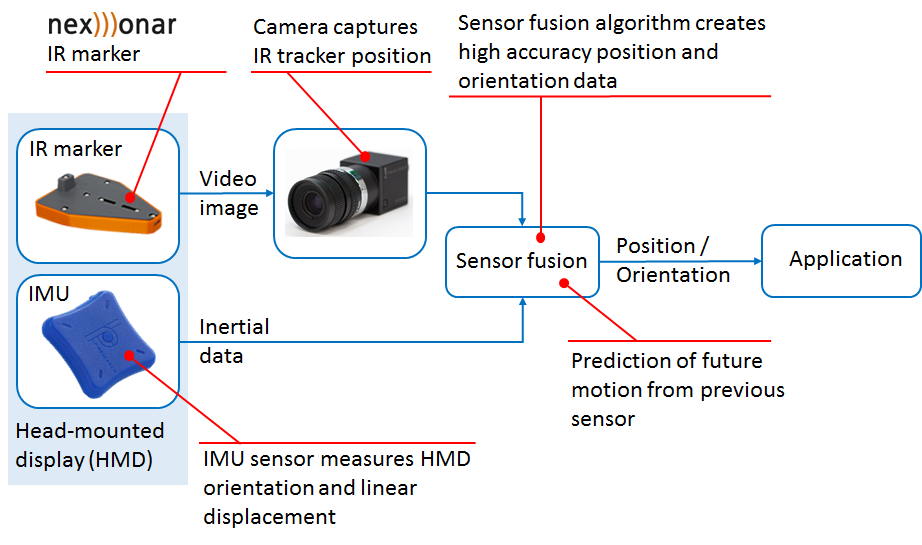

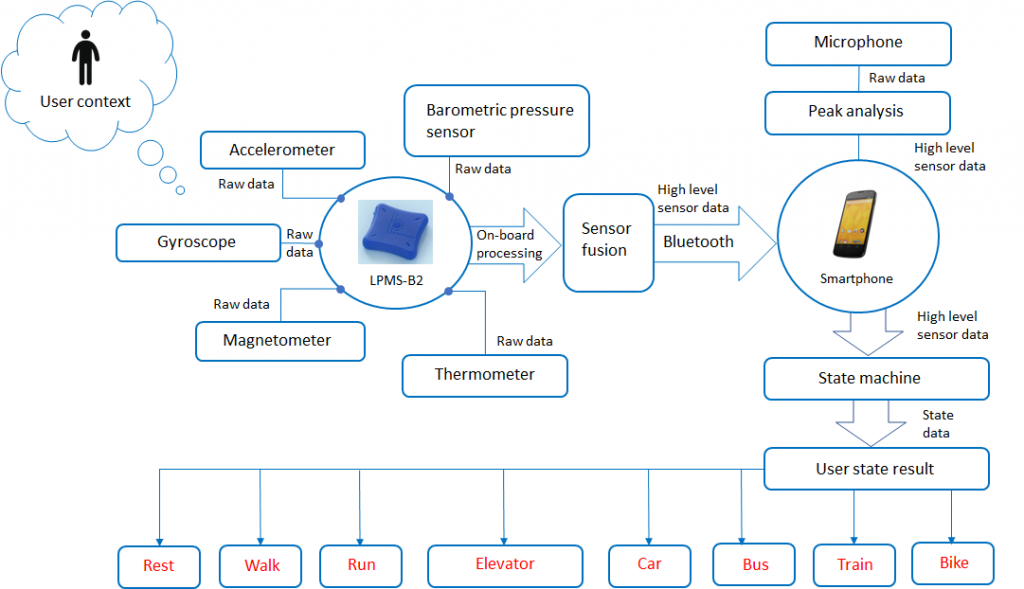

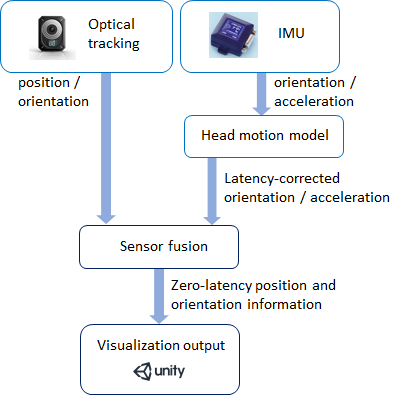

Our locations-based VR / large room-scale tracking solution solves this problem by combining optical tracking information with inertial measurement data using a special predictive algorithm based on a head motion model.

| Compatible HMDs: | HTC VIVE, HTC VIVE Pro |

| Compatible optical tracking systems: | Optitrack, VICON, ART, Qualisys, all VRPN-compatible tracking systems |

| Compatible software: | Unity, Unreal, Autodesk VRED, all SteamVR-compatible applications |

This location-based VR solution is now available from LP-RESEARCH. Please contact us here for more information or a price quotation.

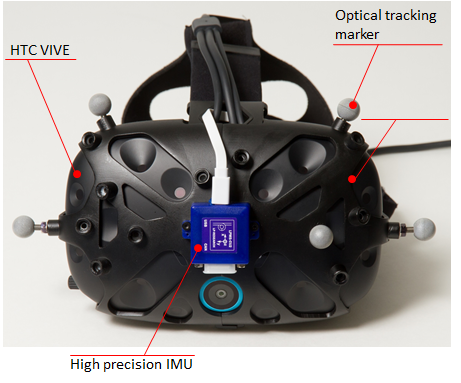

IMU and Optical Tracker Attachment

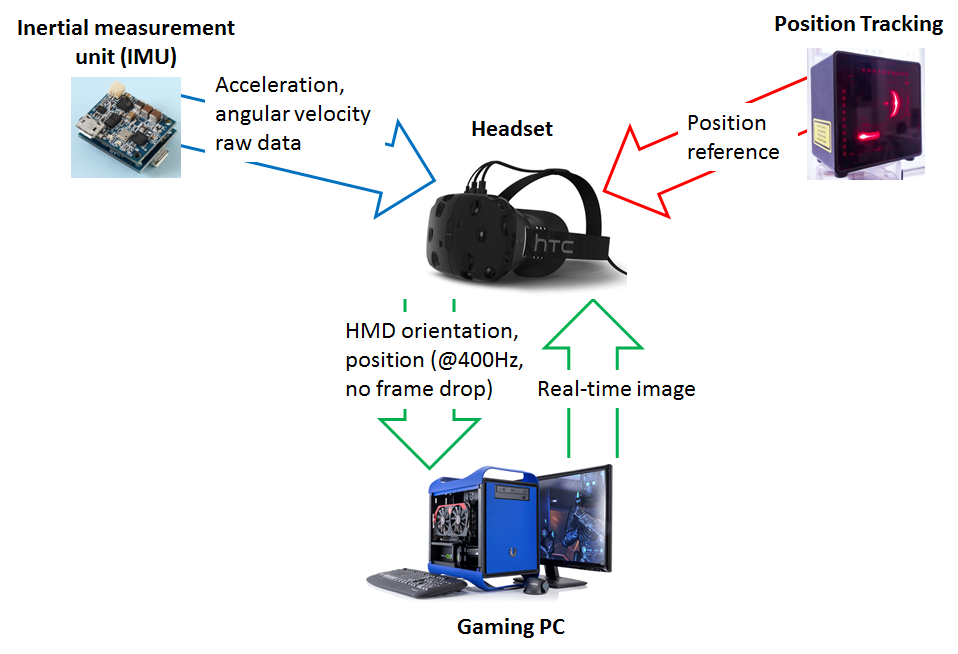

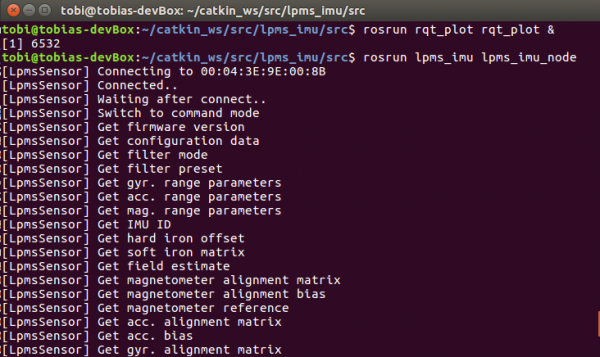

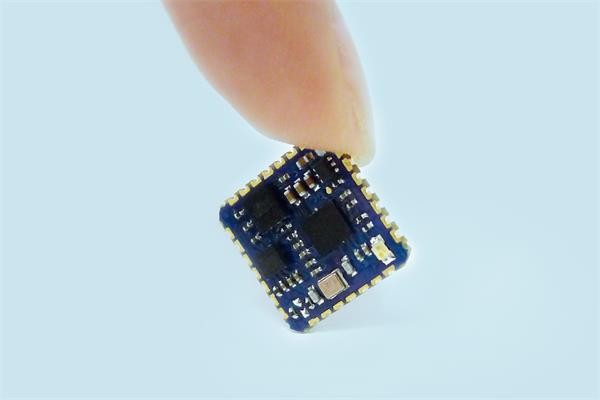

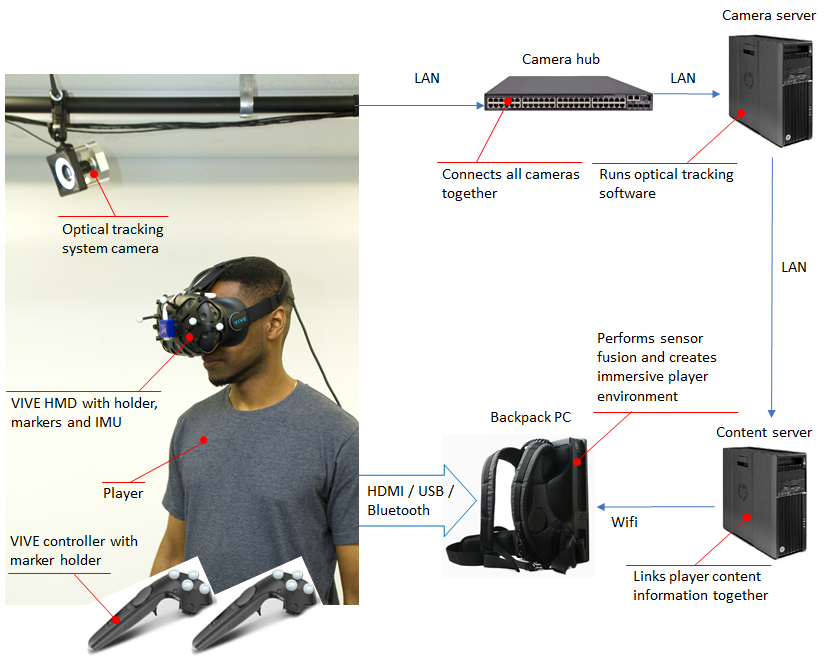

The system follows each HMD using a combination of optical and IMU tracking. A special 3D-printed holder is used to attach a high-quality IMU (LPMS-CU2) and optical markers to an HTC VIVE headset.

To create a perfectly immersive experience for the user, optical information is augmented with data from an inertial measurement unit at a rate of 800Hz. Additionally to the high frequency / low-latency updates, a head motion model is used to predict future movements of the player’s head. This creates an impression of zero latency gameplay.

Tracking Camera, HMD and Player Setup

In its current configuration the system can track up to 20 actors simultaneously, each holding a VIVE controller to interact with the environment. Players wear backpack PCs to provide visualization and audio.

Playground and Camera Arrangement

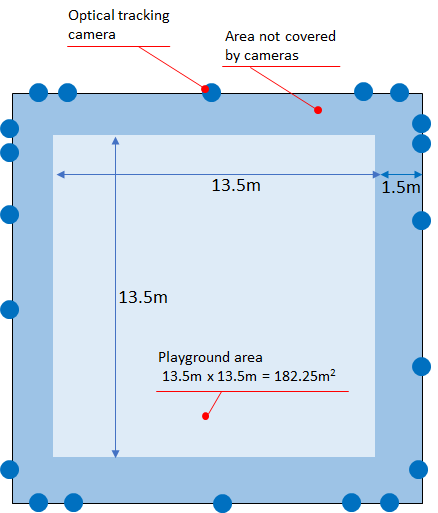

The solution covers an area of 15m x 15m or more. There is an outer border of 1.5m that is out of the detection range of the cameras. This results in an actual, usable playground area of 13.5m x 13.5m. The overall size of the playground is 182.25m². The cameras are grouped around the playground to provide optimum coverage of the complete area.

Contact us for further information.