LPNAV: Automatic Guided Vehicle Positioning System

Overview

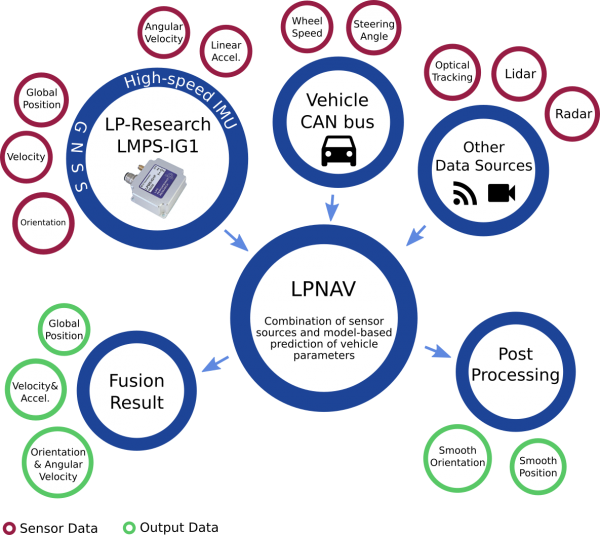

LPNAV is an automatic guided vehicle (AGV) navigation system that combines IMU, optical, GNSS and odometry data to calculate accurate position information. The accurate detection of a vehicle’s position is important for many types of robotics devices, such as vacuum cleaning robots and autonomous cars.

In outdoor environments, GPS can be used to determine location with sub-meter accuracy. In indoor environments the GPS signal is not available and other measures to acquire position information need to be used such as tracking beacons or optical markers.

Usually a single tracking method is not sufficient to provide higher degrees of accuracy and system responsiveness. With LPNAV we introduce a modular solution that is based on the core technology of our inertial measurement units (IMU) and allows the fusion of various signal sources to calculate accurate and reliable position information.

Application Areas

Automatic Guided Vehicles (AGV)

Autonomous Driving

Warehouse Logistics

Supported Input Sources

The method of combining several data sources is called sensor fusion and the accurate modelling of the vehicle’s dynamics and steering system allows for the prediction of the vehicle’s movement parameters if sensor data is not available or unreliable with centimeter-level accuracy.

LPNAV can process data from diverse sensor sources like global navigation satellite systems (GNSS), indoor optical navigation systems or camera sources to compute the best estimate of the vehicle’s position and orientation.

Example Data

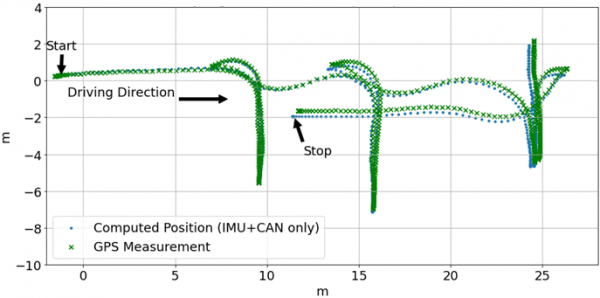

Forklift Tracking

To track forklifts inside a warehouse we developed a sensor fusion system that combines odometry data collected from the forklift CAN bus and orientation data from an LPMS-IG1 IMU. To show the accuracy of our algorithm we compared the resulting location data with a GPS reference. For an actual application case the result of the odometry-IMU fusion can further be enhanced with a global reference signal from an optical tracking source, RTK-GPS etc.

The figure above shows a Jungheinrich forklift driving forward and backwards to simulate the pickup and placement of palettes. The accumulated error of the computed position using IMU and CANBUS data is 0.46m compared to the reference GPS measurement.

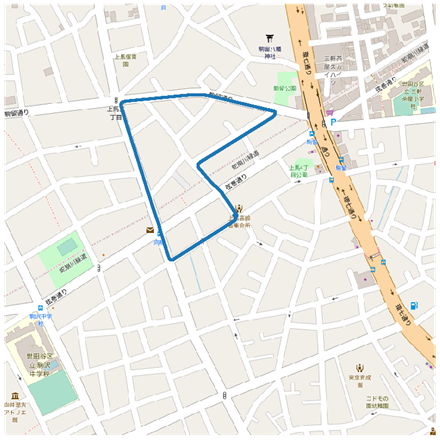

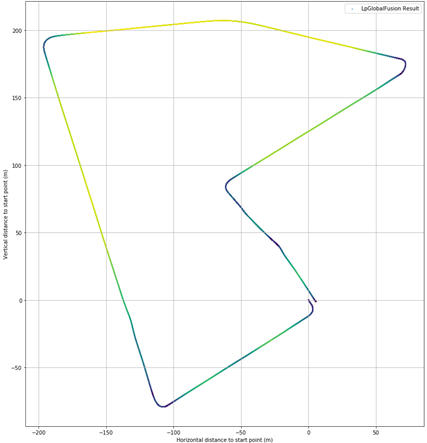

Automotive Tracking

IMU + odometry tracking can also work to determine the location of an automotive vehicle in areas where GPS is not available or the signal is not reliable. The images below show a 2km route driven in an urban environment. The graph on the left shows the reference track, the graph on the right shows the track as calculated from IMU + odometry data only. The car returned to the start-point at the end of the drive. The calculated start-and end-point are less than 5m apart.

Specifications

| Product name | LPNAV |

| Supported Platform | Linux (ARM, x64) and Windows |

| Packaging Options | Standalone application with web interface Dynamic library Unity plugin |

| API options | C-API and REST web API |

| Vehicle models | Four-wheeled vehicle with Ackermann steering model Two-wheeled vehicle Simplified vehicle model with one wheel |

| Supported inertial measurement unit | LPMS-IG1 high-precision 9-axis inertial measurement unit LPMS-IG1P high-precision 9-axis inertial measurement unit with GPS receiver and optional centimeter-level RTK-GPS unit |

| Supported vehicle dynamics sources | CANBUS interface via OBD-II and PEAK-CAN-USB for direct access to CANBUS data |

| Supported absolute positioning input | Global Navigation Satellite System (GPS, GLONASS, BeiDou, Galileo), interface for indoor positioning input NMEA source via network or serial port |

| Position and Orientation update rate | Up to 1000 Hz |

Order

Please contact us for more information.

*LP-Research is a Japan-based company headquartered in Tokyo.

- Direct transactions with our company are possible.

- Payments can be made in Japanese yen.

- All products are shipped from Japan